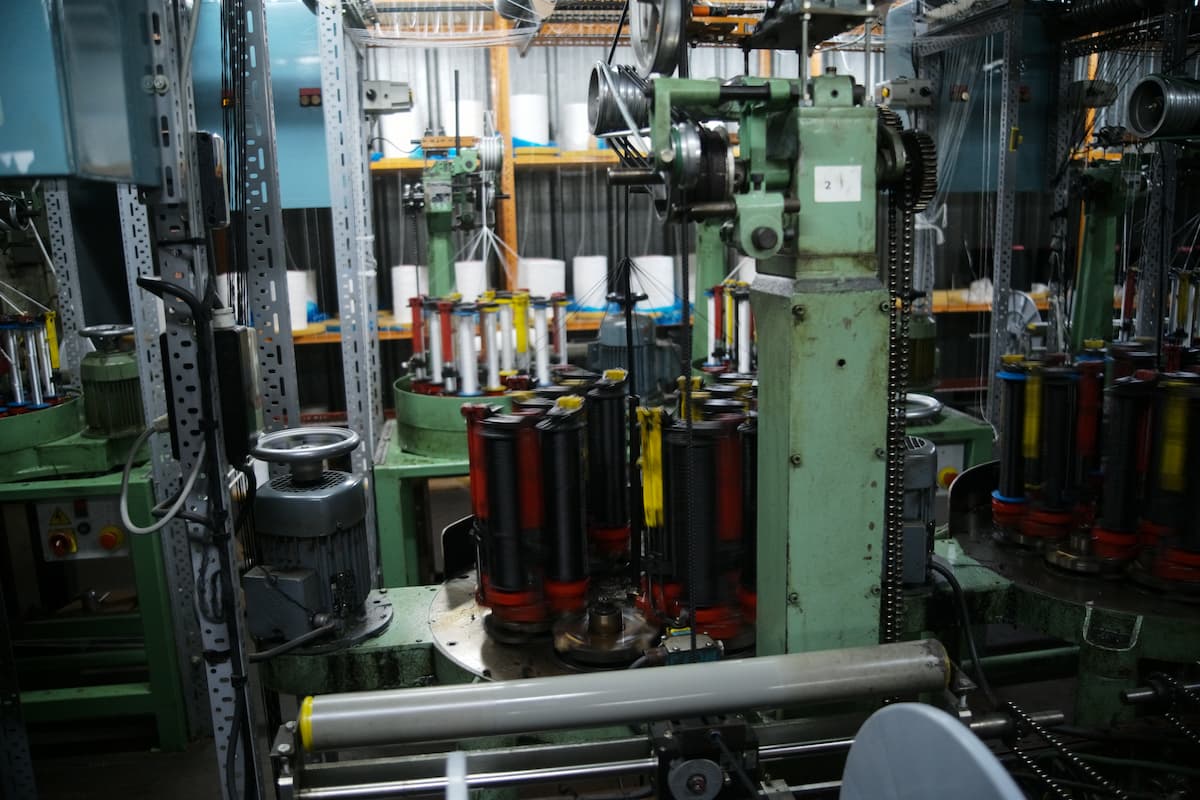

Braiding is the oblique assembly of yarns. Sigier Capelle masters the industrial expertise of choosing yarns (material, titration, number of strands) and assembling them at an angle to produce the product requested by its customers.

In short, Sigier Capelle is an industrial assembler of yarns using the braiding process.

With 5,000 spindles, we manufacture braids with or without cores, round, flat, tubular or elastic.

Flat braids, flat tubular braids and round braids are available in a range of diameters and mesh sizes.

Our machinery is regularly updated to keep up with the latest technology. In addition, our braiding machines are equipped with computer-controlled control systems developed in-house.

If necessary, Sigier Capelle uses SCF’s braiding machines (www.scfl.fr). In order to guarantee traceability, the customer is informed in the event of production on SCF’s site. We also offer weaving and knitting services through SCF.

Discover our different products !

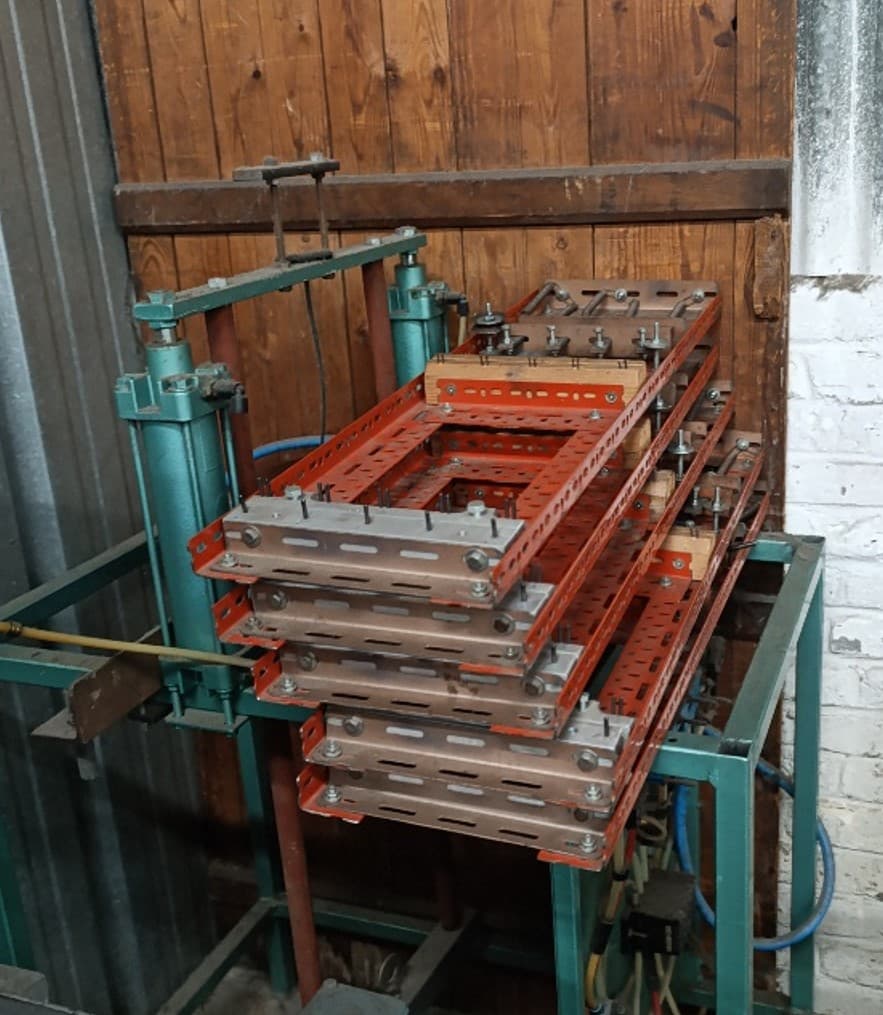

Sigier Capelle has an autoclave using ‘air cushion’ technology, which is particularly economical.

This installation has won an award from the French Water Agency.

This autoclave enables us to dye hanks, apply treatments and steam our braids.

With almost 200 years of industrial expertise, we remain the leader in large technical sewing threads, thanks in part to our special treatments.

In addition, Sigier’s finishing workshop carries out treatments for other sectors such as medical and industrial.

With 100 fulling and/or autoclave spindles, we offer a range of water-repellent, sticky, waxed, thermal or anti-fouling treatments…

Sigier Capelle works with a plastic injector to design innovative products that meet the specific needs of industry.

This cooperation enables us to offer tailor-made solutions for demanding sectors such as battery manufacture or boilers, where performance and reliability are essential

Sigier Capelle offers a wide range of assembly operations, from sewing and fitting ferrules to more complex assemblies.

As a result, Sigier Capelle can clip plastic parts onto braids. We can also thermoform plastics onto braid and form handles and sleeves.

These assemblies are carried out with precision by our experienced staff.

In this way, Sigier Capelle provides our customers with a turnkey solution. Do not hesitate to contact us.

Sigier Capelle provides its customers with technical data sheets indicating the composition of the braid, the type of machine used and any treatments applied.

Sigier Capelle can also carry out physical tests on the braids.

Packaging is an essential stage in the transport and use of the final product. When a new product is introduced, the customer determines the desired packaging.

We have been able to adapt to our customers’ needs by offering cold or hot cutting, precision parallel or cross-winding, and processed bulk (economical and environmentally friendly thanks to the reduction in packaging).